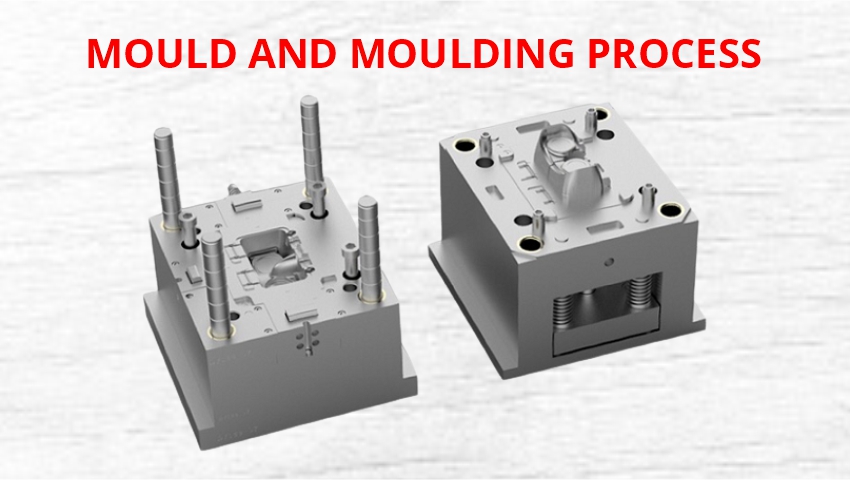

Mould And Moulding Process

Moulding is the process of shaping material to fit into the desired form. This process can be carried out by hand, or with the help of machines. An object that is used to create the desired shape is called the “mould”.

Steps for Moulding Process at Vocal Tech

Mould design

Mould design is the process of designing the shape of a mold by considering factors like dimensions, gate locations, shear edges, material, cooling, and ejection techniques. Moulds are usually made out of metal but can be made out of other materials like silicone or plastic. The design of moulds not only determines the quality of products but also determines production efficiency and machine life.

Injection

This process is done by injecting the plastic material between two metal plates that are shaped like the desired shape and then heating the metal plate to make it harden.

Clamping

clamping is a process in which molten metal is poured into a mould. The molten metal cools and solidifies to form the desired shape. The clamps are used to hold the mould together during the cooling process. The clamps are usually made out of wood or metal and they are attached to the edges of the mould using screws.

Cooling

The cooling process is an important part of the production line. It is the last step before the moulded product is taken off the machine. The cooling process prevents any deformities in the product and also helps to prevent any breakages later on. The cooling process usually takes around two minutes and it can be done by several different methods.

Ejection

An ejection in moulding process is the separation of casting from the die and the separation of core boxes.

Mould Opening Process

The mould opening process is a complicated one. To get the best results, it is important to have a deep knowledge of the shape and material used for castings. Opening of mould should be done without damaging the moulded part.

Applications of Mould and mould design in Different Industries

Mould and mould design is used extensively as it has advantages like low cost, high flexibility for the design of a product, high production rate, and low labour cost. They are used in the Packaging industry, Automotive industry, Building and construction industry, Food, and beverage industry, Medical, and pharmaceutical industry

Vocal Tech Solutions has expertise in the Moulding process and design as we provide our design services by understanding customers’ products and the process carried out for production.

We provide our mould design services for

- Extrusion Mould

- Compression Mould

- Blow Mould

- Injection Mould

- Rotational Mould