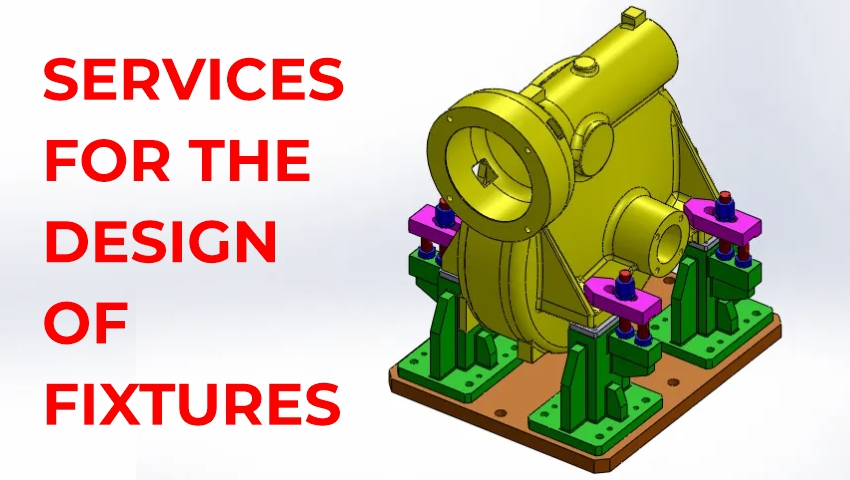

Designs of fixtures and Services

Fixtures and their Importance

Fixtures are equipment used in the design and engineering process to hold the workpiece and to create a stable, repeatable, and uniform product. They are used to ensure the quality of a product or system by providing an accurate, consistent, and reliable platform for testing.

A fixture is an essential tool for engineers and designers to assess the performance of their designs in real-world conditions. They are used to simulate different scenarios that would otherwise be difficult or impossible to replicate in a laboratory environment. Design fixtures are an invaluable part of any engineering process, as they allow for accurate testing and evaluation before production begins.

Uses of Fixtures in Manufacturing Process

- Fixtures ensure that products are manufactured consistently and reliably.

- They are used to hold components together while assembling different components and help to keep the parts in the correct position during assembly.

- Fixtures help manufacturers save time and money by streamlining the production process and ensuring that all parts fit together correctly.

- Fixtures improve safety by reducing the risk of injury or accidents caused by incorrect assembly.

- Manufacturers can produce high-quality products with higher speed and accuracy by using fixtures, resulting in increased customer satisfaction.

Steps followed at Vocal Tech for the design of fixtures

Step 1: Define Requirements

In this step, we determine what type of materials to be used, what size and shape of the fixture should be, and what different features are needed. It is also important to consider how the fixture will be used in production and what safety measures need to be taken into account. Defining these requirements beforehand will ensure that all aspects of the design process are taken into consideration when creating a successful fixture.

Step 2: Gather/Analyze information

Gathering and analyzing information helps designers to understand the user’s needs and expectations. Step- 2, designers can create effective designs that meet their users’ needs. This step helps the designers to understand and identify the problems that may arise during the design process. Gathering and analyzing data also allows designers to make informed decisions about their designs. With this information, they can create an efficient and effective design for their users.

Step 3: Develop Several options

A fixture is used to test and evaluate a product or system’s performance. This step involves creating multiple prototypes, testing them, and then selecting the best one that meets the requirements. At this stage, designers need to consider all aspects of the design including usability, cost, materials, and other factors. By developing several options in Step 3 of the design fixture process, designers can ensure that they can identify the best solution for their product or system.

Step 4: Choose the best option

This step requires careful consideration and analysis of the different options available. Consider factors such as cost, quality, reliability, and other criteria to select the most suitable fixture for your project.

To make sure that you choose the best option for your design fixture, it is important to compare different solutions and evaluate them according to their features and benefits. Once you have narrowed down your options, you can make a final decision based on which one offers the best value for money. By following these steps, you can ensure that you select a design fixture that meets all of your requirements and fits within your budget.

Step 5: Implement the final design

Once the design is final, it is time to implement it. This process involves putting the design into action by executing the plan and making sure all elements are in place. This step includes creating a timeline for implementation, setting up any necessary tools or software, testing the design, and making sure it works as intended. After this step, you should have a fully functioning product or service ready for use!

Engineering design solutions at Vocal Tech Solutions

Vocal Tech Solutions aims to provide the best Mechanical and Engineering design solutions as our designs are prioritized to bridge the gap between the design table and shop floor. List of our Mechanical Design Engineers deliver services –

- Concept Development

- Detailed engineering drawings with 2D documentation

- 3D solid and surface modeling

- Value engineering through prototypes

- 3D CAD modeling

- Data-backed designs with engineering analytics

- Design automation and CAD customization

- Design optimization with FEA and CFD solutions

- Reverse engineering services for remanufacturing